R&J Waste Water Treatment Organization is dedicated to delivering advanced and reliable sewage treatment solutions for residential, commercial, and industrial projects. In today’s world, effective wastewater management is not just a requirement but a responsibility. One of the most widely used and efficient technologies in modern stp is MBBR. Efficient sewage treatment prevents harmful pollutants from entering rivers, lakes, and groundwater. Treated water can be reused for gardening, flushing, and cooling systems, reducing freshwater consumption.

MBBR Full Form

The mbbr full form in stp is Moving Bed Biofilm Reactor. This advanced biological treatment process is used in Sewage Treatment Plants (STP) to treat wastewater efficiently. The mbbr stp full form clearly explains the working principle—moving bed biofilm reactor—where biofilm grows on specially designed plastic media that move freely inside the reactor tank. The mbbr tank full form refers to the Moving Bed Biofilm Reactor tank, which is the core component where this biological activity takes place.

Why MBBR is Used in STP

The mbbr stp full form is not just a technical term; it represents a modern solution to wastewater challenges. There are several reasons why this technology is widely adopted in sewage treatment plants:

- High Treatment Efficiency: The Moving Bed Biofilm Reactor provides a larger surface area for microbial growth, leading to better removal of BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand).

- Compact Design: Systems based on the stp mbbr full form concept require less space compared to conventional activated sludge processes. This makes them ideal for urban areas where space is limited.

- Easy Operation: The mbbr full form in stp technology is relatively simple to operate and maintain. It does not require complex sludge recycling systems.

- Flexibility: MBBR systems can handle variable loads, making them suitable for residential complexes, hotels, hospitals, and industries.

At R&J Waste Water Treatment Organization, we provide customized MBBR-based STP systems that are designed according to project requirements and environmental standards.

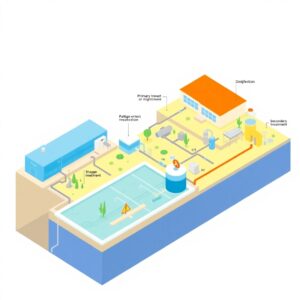

Components of an MBBR STP

To fully understand the mbbr full form, it is important to look at the key components involved in the process:

- Equalization Tank: This tank collects incoming wastewater and ensures uniform flow into the treatment system.

- MBBR Tank: The mbbr tank full form, or Moving Bed Biofilm Reactor tank, is where biological treatment occurs. Special media carriers are added here to support microbial growth.

- Aeration System: Air diffusers supply oxygen to keep the carriers moving and maintain aerobic conditions necessary for bacteria to survive.

- Secondary Clarifier: After biological treatment, the water flows into a clarifier where suspended solids settle down.

- Filtration and Disinfection: Treated water is filtered and disinfected before being reused or discharged safely.

Each stage works together to ensure effective wastewater treatment. R&J Waste Water Treatment Organization designs these systems carefully to provide long-lasting and energy-efficient solutions.

Also Read : What is a Water Treatment Plant and Its Importance in Preventing Water Pollution

Advantages of MBBR in STP

When people search for the mbbr full form in stp, they are often looking for the benefits as well. Here are some key advantages:

- Improved biological treatment performance

- Lower sludge production

- Reduced operational issues

- Ability to upgrade existing STPs easily

- Stable performance under fluctuating loads

Because of these benefits, the mbbr stp full form technology is becoming a preferred choice across India and globally.

Applications of MBBR Technology

The stp mbbr full form technology is widely used in:

- Residential apartments

- Commercial buildings

- Shopping malls

- Hospitals

- Educational institutions

- Industrial facilities

R&J Waste Water Treatment Organization has extensive experience in designing and installing MBBR-based sewage treatment plants for diverse sectors. We understand that every project is unique, and therefore we offer tailored wastewater treatment solutions.

Why Choose R&J Waste Water Treatment Organization?

When it comes to implementing the mbbr full form in stp technology, choosing the right partner is essential. R&J Waste Water Treatment Organization combines technical expertise with practical experience. Our team carefully analyzes site conditions, wastewater characteristics, and client requirements before recommending a solution.

We offer end-to-end services including:

- System design and engineering

- Installation and commissioning

- Operation and maintenance support

- Upgradation of existing STPs

Our focus is on delivering efficient, cost-effective, and eco-friendly wastewater treatment systems that meet long-term needs.

The mbbr full form in stp stands for Moving Bed Biofilm Reactor, a modern and highly efficient biological treatment technology used in sewage treatment plants. The mbbr stp full form and stp mbbr full form both refer to this innovative system that enhances wastewater treatment through biofilm-based processes. The mbbr tank full form highlights the core reactor where the treatment occurs. R&J Waste Water Treatment Organization proudly provides advanced MBBR-based sewage treatment plant that ensure clean water and a cleaner environment for future generations.